Using more mechanization in a vineyard -- beyond just mechanical harvesting -- can reduce labor costs without negatively affecting grape quality, according to a presentation Wednesday at the Vineyard Economics Symposium. It might even make the grapes better.

This is important because in an annual survey of vineyard owners, 54% listed listed labor shortage and costs as one of their most important issues in 2020 -- and this was before the Covid-19 lockdown. In 2019, labor shortage and costs were the No. 1 overall concern.

"Vineyard size has increased in California due to consolidation," said S. Kaan Kurtural, associate specialist for cooperative extension viticulture at UC Davis Department of Viticulture & Enology. "Mean acreage is approaching close to 260 acres. It's hard to get to all these vineyards in a normal amount of time. The cost of labor has gone up: $15 an hour plus benefits, recently. Also, people don't want to work in vineyards anymore. And vineyards are a rural industry, not close to population centers. People have to be driven from populated areas."

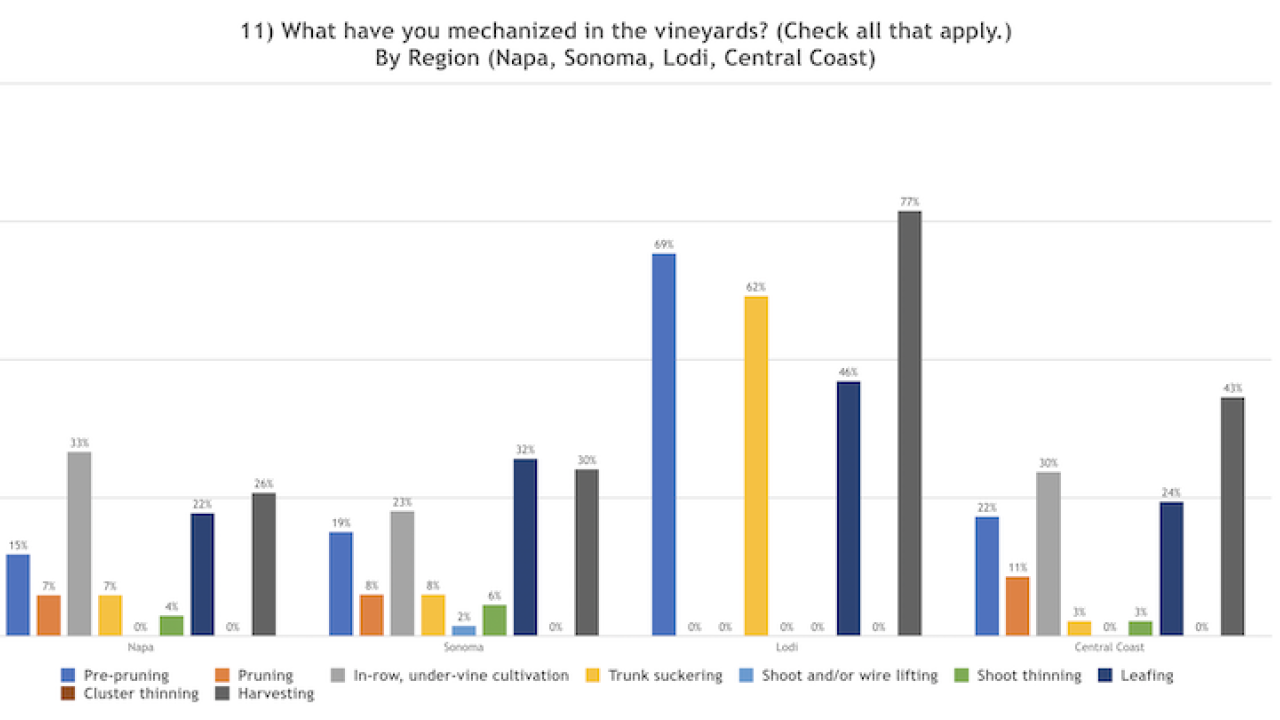

However, most vineyard owners still don't think of mechanization beyond harvesting, though the equipment to mechanize many more processes is available.

"If you're just trying to dip your toes into mechanization, leaf removal and harvest are the two easiest things to do," said Greg Gonzalez, director of vineyard operations for Scheid Family Wines, which manages 4000 acres of vineyards in four AVAs on the Central Coast. "Harvest, about 90% is done that way. But leaf removal, the technology has been here quite a long time."

Kurtural presented results of several studies iincluding an explanation of the "touch free" experimental vineyard UC Davis established in Oakville. Everything that can be mechanized in this Oakville vineyard has been.

"It's all 5-foot by 6-foot spacing, Cabernet (clone) 3309," Kurtural said. "Essentially no human touches it. It's very interesting, in the middle of To Kalon."

Kurtural, who joined UC Davis in 2015 from Cal State Fresno, is a prolific researcher into the effects of mechanization. His first lead citation on the impact of mechanization on grapevines was in 2009. In 2012 he co-authored a study titled, "Mechanical canopy management reduces labor costs and maintains fruit composition in Cabernet Sauvignon grape production." He has also studied the impact of mechanical canopy management on the phenolic composition of Syrah.

One of his findings was counterintuitive for farmers who prefer doing things by hand.

"When we looked at methoxypyrazines, if we had hand-pruned, we were manufacturing the most methoxypyrzaines," Kurtural said. "We were hardly making any methoxypyrazines with a mechanically managed vineyard."

Methoxypyrazines are the class of chemicals that give wine a "green" flavor, and that many red-wine growers try to avoid. Kurtural said hand pruners tend to open up the grapevines in such a way that they form methoxypyrazines that the berries do not lose later.

Kurtural told Wine Business Monthly after the presentation that his research shows that not only is overall grape quality for Cabernet Sauvignon, Merlot and Syrah the same with mechanical vineyard management -- in some cases, it's better.

"It's a repeatable process," Kurtural said. "There's very little year to year variation. For Syrah, Merlot, Cabernet, it holds true. We didn't work with other varieties. Seventy percent of the crush in California comes from within a 100 mile radius of Fresno. These grapes are more and more farmed by machine. Growers have fine-tuned these machines quite well."

Kurtural said the trellis type is crucial for allowing future mechanization choices. The experimental no-touch vineyard in Oakville uses a single high-wire system, which allows easy mechanization of all vineyard activities.

A VSP system is also good for mechanical harvesting, pre-pruning and leaf removal, and is OK for trunk suckering. But it is more difficult to mechanize shoot thinning, berry/cluster thinning and final pruning on a VSP system. And leaf removal is more challenging to mechanize with a California sprawl or head training system.

That may be why, though 90% of California vineyards are mechanically harvested, and 65% are mechanically pre-pruned, only 45% have mechanized leaf removal. Other processes are even less mechanized: just 7% of shoot thinning, 7% of fruit removal, and 2% of shoot positioning.

In an earlier session, vineyard consultant Lise Asimont said that the quality of mechanization equipment has something to do with that. Asimont said the quality of mechanical harvesters and leaf removers is well-established.

"If there are any equipment companies out there, this is an indication that the market is not pleased with the equipment available for shoot thinning," Asimont said. "Great opportunity there."

Kurtural also said that his research shows that water stress is not always being properly applied. He told Wine Business that his results showed the best grape quality came from this system: "We irrigate them to 70% of demand to fruit set. We cut it to 50% of demand between fruit set and veraison. Then ramp it up to 70% from veraison all the way to harvest."

Many growers watching the symposium on their home computers wanted to know about cost of mechanization.

"When we did our Napa Valley budget, when we did the calculations, other than harvesting, our savings average was 86%," Kurtural said.

Kurtural said that even with the cost of buying the equipment, "the break-even point for us was 18 months."

Also, a 2019 study he co-authored showed that over three years, a Merlot vineyard in the San Joaquin Valley that converted to complete mechanization showed a greater profit, even after the cost of the equipment.

Kurtural also said that he has done blind tastings of wines from the same vineyard, one portion mechanically managed and the other managed by hand, and that in every case, the wine from the mechanically managed vineyard was preferred.

"People were quite surprised," he said.

That would be no surprise to Gonzalez, who said that Scheid Vineyards has mechanized as much of its operations as fits into their core culture.

Gonzalez said that mechanizing vineyard operations doesn't save time -- but it does require fewer people.

"Grapes take the same amount of time to manage regardless of the mode of management," Gonzalez said. "We have nearly the same hours. The hours haven't gone down. But we are using fewer people We're getting more done with fewer people. Those people are getting more hours."

In this way, Scheid is able to have more of its vineyard tasks performed by staff workers, and fewer by outside companies.

"That's what we're focusing on: how can we cut those outside labor costs," Gonzalez said. "We have to compete for those."